Steelco AC MITO 3500

Steelco MITO AC 3500

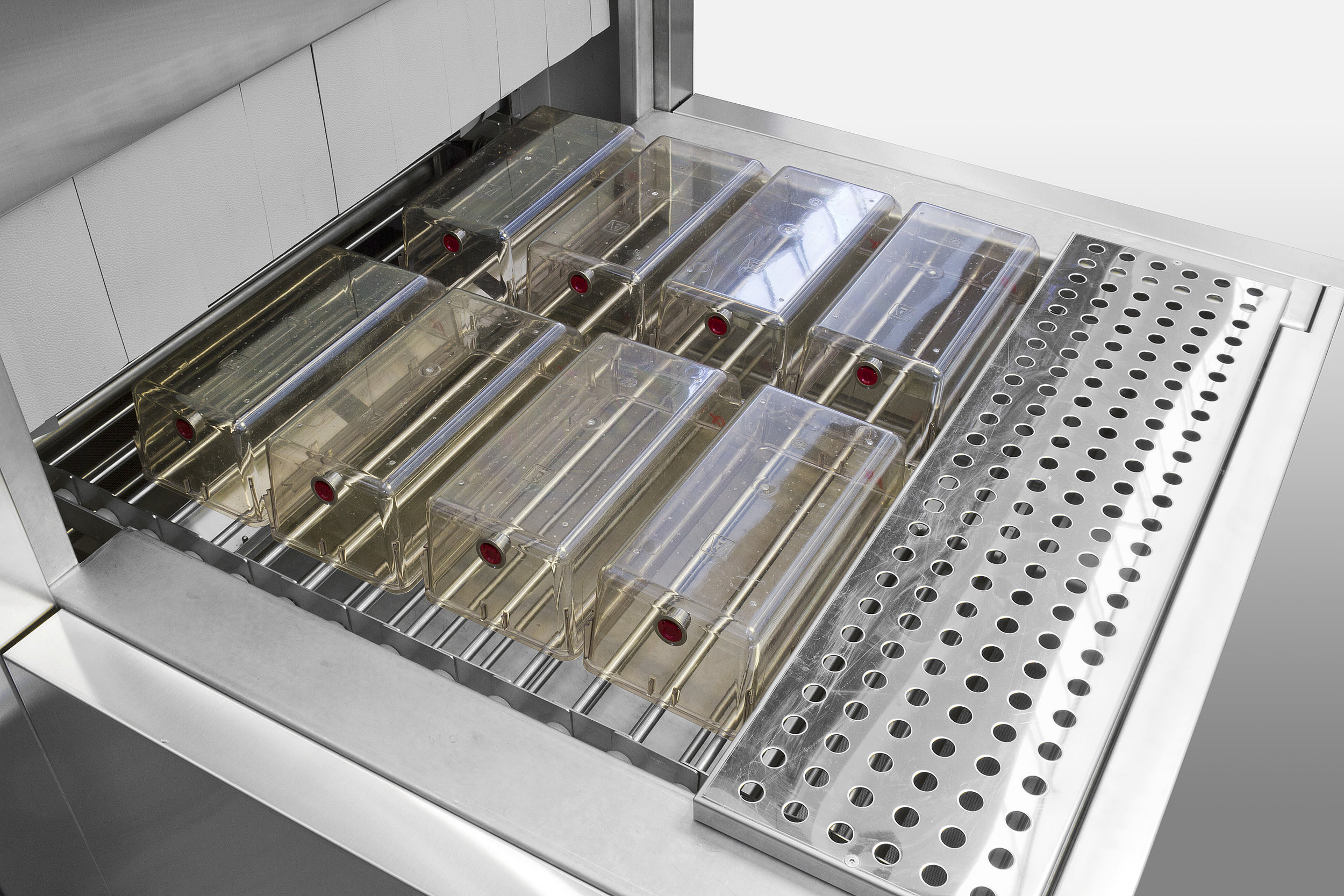

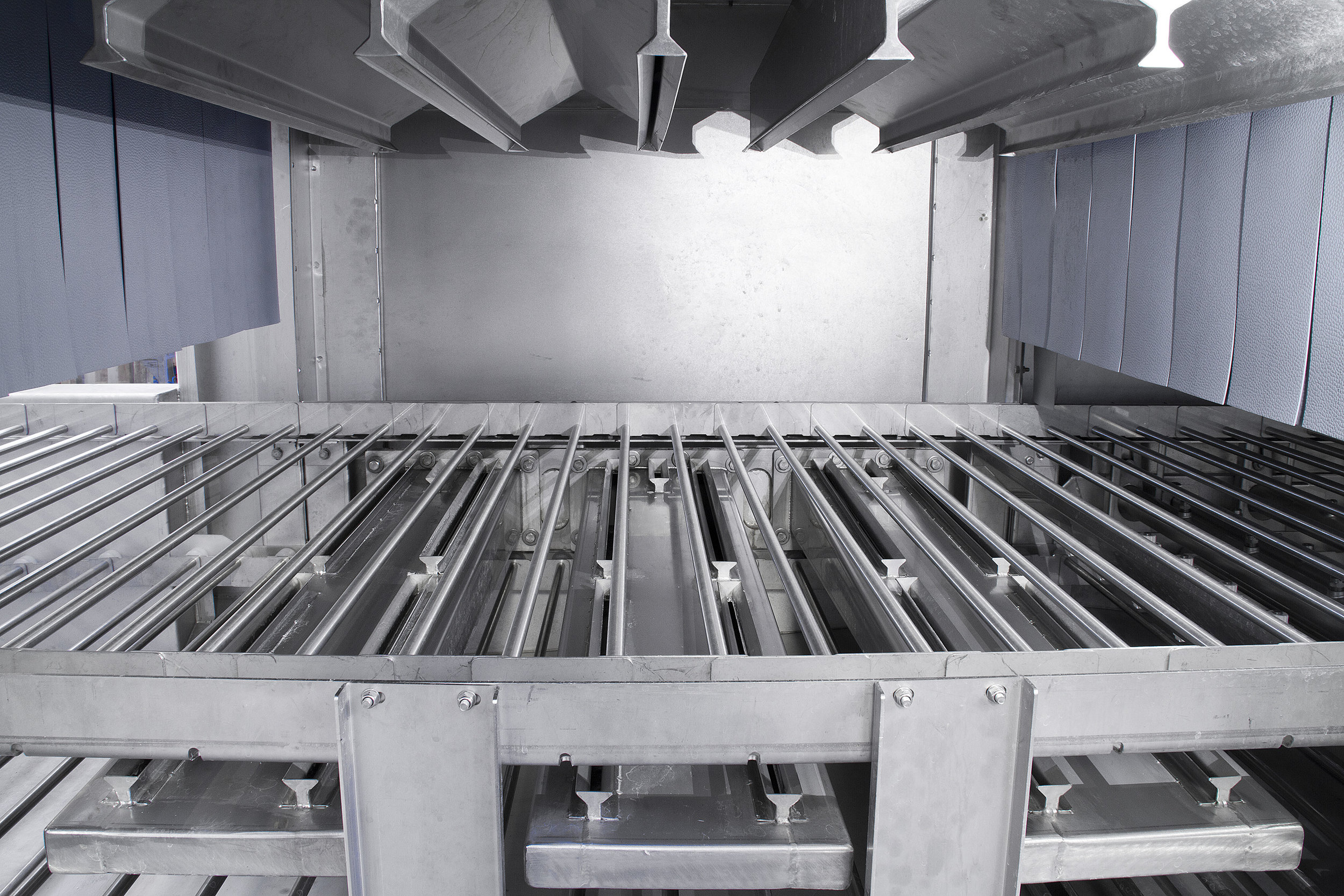

To support the growing demand of compact systems for the automatic processing of animal cages, the MITO AC 3500 provides an integrated and flexible solution. The system is composed of modules with dedicated functions (pre-wash, acid/alkaline wash, rinse/final rinse, blow down and hot air drying) for the processing of almost any type of animal cages available on the market.

Modules can be added or removed for customized solutions. Each tunnel chamber is equipped with a vertical sliding glass door for visual inspection. The AC 3500 combines high pressure and flow rate to provide outstanding washing and rinsing performances, washing up to 750 cages per hour. Despite the powerful action and massive water flow, the AC 3500 provides a significant reduction of water consumed.

Automated Loading/Unloading System

Modern facilities for animal laboratory research require technological equipment in order to deal with the increasing demand for productivity. MITO AC 3500 can be configured with an automation system even in a later stage.

The automation system is characterized by:

- Transport pallets for the handling of stackable cages

- Automatic conveyors for loading and unloading stations

- Programmed robots for the emptying and loading of the dirty cages on the tunnel washer belt as well as picking up, filling with new bedding and stacking on the cage transport pallets

- Control station in the loading zone